Solutions

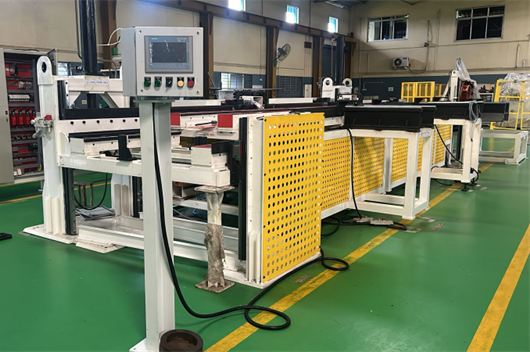

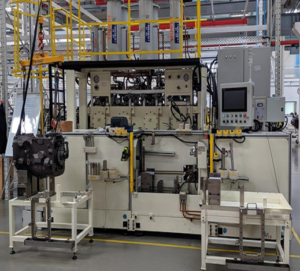

Automated Assembly Line

Major

Pick & Place Arrangement or Bowl feeder for child parts feeding.

Conveyorized Arrangement to move different stages via pallet.

Multistation for each process.

Quality Inspection using Vision system.

End to End Traceability for product.

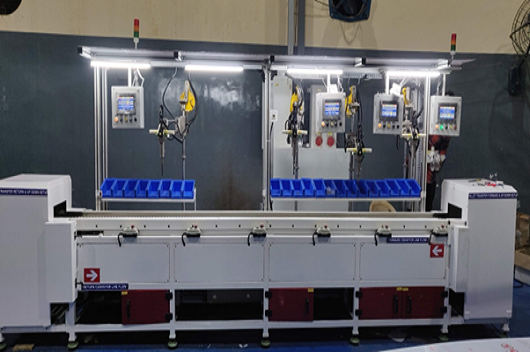

Lean Assembly Cell

Reduced movement and handling improve workflow efficiency.

Consistent and standardized processes enhance product quality.

Faster turnaround times and increased throughput contribute to higher profitability.

Change over type fixture arrangement for different variants & products.

Optimized workstation layouts reduce physical strain on workers.

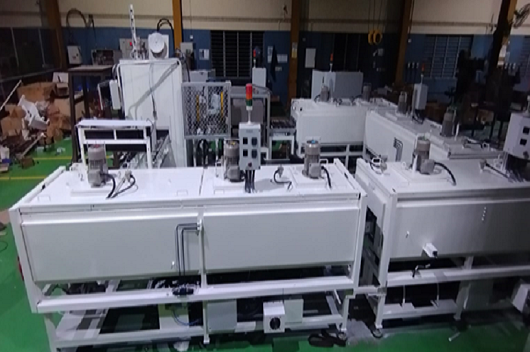

Automated Conveyors

Pallet transfer mechanism to different stations.

Bowl feeder arrangement for child part feeding.

Robotic Arrangement for Glue Dispensing.

Spring Balancer with Nut runner Integration.

Complete End to End Traceability of the Product.

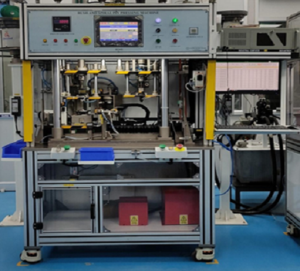

Test Rigs

Performance Test Rig.

Leak Test Rig through wet (oil, water) & dry.

Endurance Test Rig.

Usage of Leak Detectors for air leak test.

Inspection Equipment

Material Handling Equipment

Dynamic Techno Systems offers a comprehensive range of material handling equipment designed to optimize efficiency, safety, and productivity across various industries. Material handling equipment plays a crucial role in modern industrial and commercial environments by facilitating the movement, storage, protection, and control of materials and products.

Conveyor – Belt, Roller & Chain, Product Location Bins, Pallets, Material Movement Trolley, Child Part Storage

Designing

We take pride in offering complete end-to-end design solutions for our clients, ensuring that every stage of the design process is expertly managed in-house. Our design department is equipped with cutting-edge technology and a team of highly skilled professionals with years of experience in machine design and engineering.

From concept development to detailed machine design, we collaborate closely with our clients to fully understand their needs and deliver innovative, tailor-made solutions. Whether designing complex systems or specialized machinery, we ensure that each project is approached with meticulous attention to detail, delivering robust solutions that meet the highest standards of quality, precision, and functionality.

Programming

We provide comprehensive programming services tailored to the evolving demands of modern industrial automation. Our expertise covers PLC programming, LabVIEW development, and robotic programming, ensuring seamless system integration and optimal performance for your machinery.

With specialization across platforms such as Mitsubishi, Siemens, Omron, Allen-Bradley, and B&R, we deliver reliable, efficient solutions that meet diverse industrial needs. Our advanced expertise in Data Traceability using LabVIEW truly sets us apart. We design and implement sophisticated data tracking systems for accurate, real-time monitoring, elevating both quality control and operational transparency.

Tools & Fixtures

We are specialised in providing custom tools and fixtures like Mechanical & Hydraulic Fixtures. Our team of experienced engineers works closely with customers to understand their specific needs and develop tailored solutions that enhance efficiency, precision, and productivity. With our advanced in-house manufacturing facility, we ensure the highest quality standards and deliver products that exceed customer expectations.